Engineering Expertise.

e-Kinesis Portfolio of Engineering services

Vehicle Electrification

Retrofit

Conversion of a conventional, internal combustion engine (ICE) vehicle, into an electric one (retrofit) allows for optimizing vehicle’s use before its withdrawal. Vehicle’s lifespan can be extended and at the same time the remanufactured vehicle maintains the same performance compared to the original vehicle, produces zero emissions and runs at lower maintenance costs.

Retrofit of an ICE technology vehicle (Diesel, petrol, gas, etc.) includes replacement of the conventional powertrain and transmission system (internal combustion engine, exhaust gas aftertreatment system, cooling system, gearbox, etc.) by an electric motor and a battery pack. At the same time, it requires integration of controls and cooling subsystems for the motor and the batteries, while it necessitates replacement of auxiliaries, the operation of which was supported by the thermal engine, in the conventional vehicle (eg air conditioner compressor).

e-Kinesis offers a state-of-the-art technical service for vehicles electrification, combining innovative products and engineering tools developed by our company.

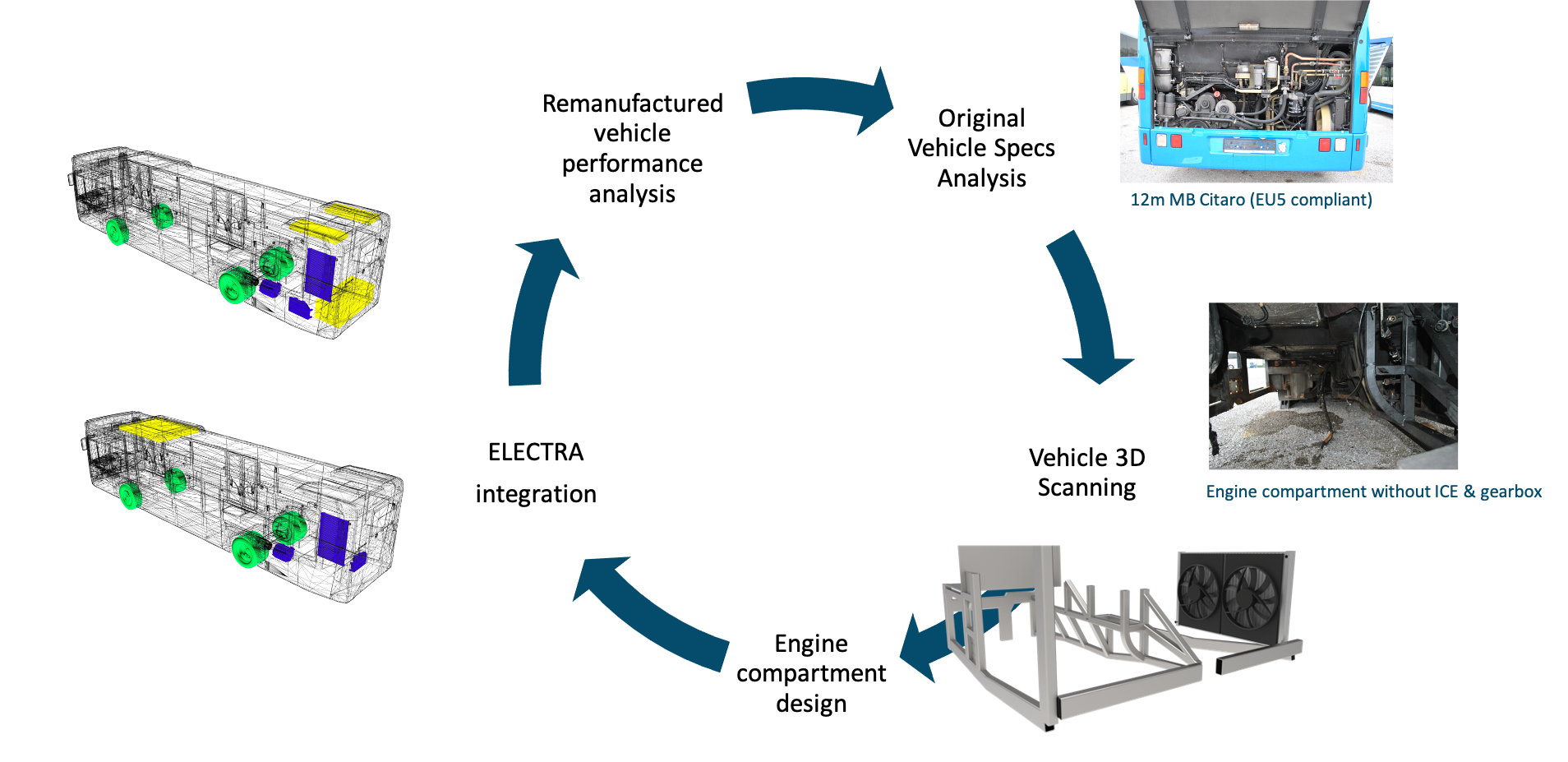

According to our methodology, the conventional powertrain and transmission systems are replaced by the innovative battery electric powertrain system Electra which has been designed by our team and can be installed on various types of vehicles, maintaining their original characteristics (performance, stability, and center of gravity). Thanks to Electra's adjustable design, we provide customizable sizing of the electric motor and the battery pack, in order to meet power, torque and autonomy requirements for each application and type of vehicle.

Using the vehicle simulator Archimedes which has also been developed by our company and under our team of expert engineers, we offer detailed analysis of each vehicle’s requirements and respective sizing of the Electra powertrain system. Finally, we employ CAD software aiming at optimizing Electra installation of Electra on each vehicle.

Battery Electric Powertrain Development

Development of a battery electric powertrain system is a technically and economically demanding process. Electric vehicles’ architecture incorporates technologically advanced components and subsystems such as electric motors, battery packs and auxiliaries, which must be properly sized and coupled through complex control systems. At the same time, cost of these components and especially that of batteries remains high, while the process of developing a battery electric powertrain system is expensive, requiring significant investment in man-effort, by expert engineers.

Thanks to our engineering team, with multi-years experience in the automotive industry, e-Kinesis offers customized engineering services related to battery electric powertrain system development. Our capabilities for studying and designing battery electric powertrain systems are summarized below:

• Mathematical modeling and simulation of the electric vehicle and its subsystems (engine, battery pack, transmission systems, etc.) using the electric vehicle simulator Archimedes, which has been developed by our team.

• Engineering studies related to design and operation analysis of battery electric powertrain systems: electric motor sizing, electrical / thermal study of batteries, energy recovery system analysis, etc.

• Know-how transfer

eV charging planning and routing services

Electric vehicles become increasingly attractive to vehicle fleet owners, thanks to their low energy consumption, competitive maintenance costs and zero emissions. On the other hand, development of an eV fleet is a complex task, requiring consideration of various factors, such as vehicle’s type and technical specifications, vehicle’s routing profile, charger’s technical characteristics, fleet maintenance cost analysis, etc.

We apply technology and engineering tools, used in RnD departments of the automotive industry to optimize charging and routing of your electric vehicles.

e-Kinesis offers the innovative technical service OeVD (Optimized electric Vehicle fleet deployment) for supporting analysis and optimization of eV fleet charging planning and routing. Combining the geographical information systems software QGIS® and the electric vehicle simulator Archimedes with an in-house developed optimization algorithm, we allow study and optimization of vehicle charging planning and routing, ensuring maximum autonomy and battery life.

Moreover, e-Kinesis in cooperation with charger suppliers and charger installation companies, is able to support the complete vehicle deployment process, from the eV charging and routing analysis and optimization to the actual charging infrastructure creation.

We offer: